SPRAY CHAMBER

The tube moving on the conveyor passes through a circular spraying ring mounted with a number of airless spray nozzles (normally).These spray nozzles are mounted on adjustable rods to adjust spraying distance from the substrate (tube outer

surface). Picture represents tube coating system. The spray nozzle size, the spraying distance and the number of nozzles depends on

Tube size (OD),

Conveyor speed, required coating thickness,

coating material specifications(viscosity etc.).

OVER-SPRAY RECYCLING SYSTEM

The over-sprayed coating material is collected at the bottom of the spray chamber. A diaphragm pump is used to pump the coating material tank through a bag type low – pressure filter.

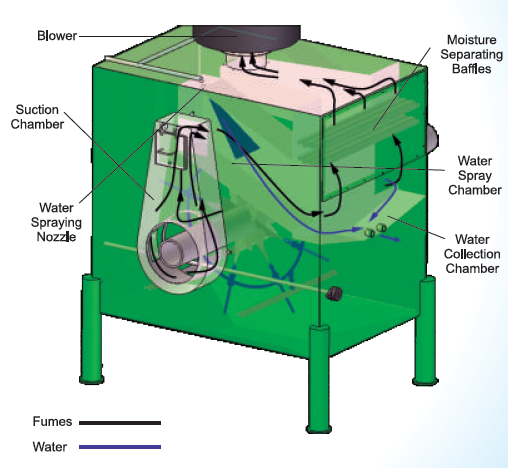

The fumes created by spray (Hot airless spray creates minimum fumes compared to any other type of spray systems) are sucked and blown out with the help of exhaust blower provided at the top of the spray chamber.

Some traces of the coating material are carried by these exhaust fumes, these fumes are first collected in suction chamber on both sides then these fumes enter in water spray chamber.